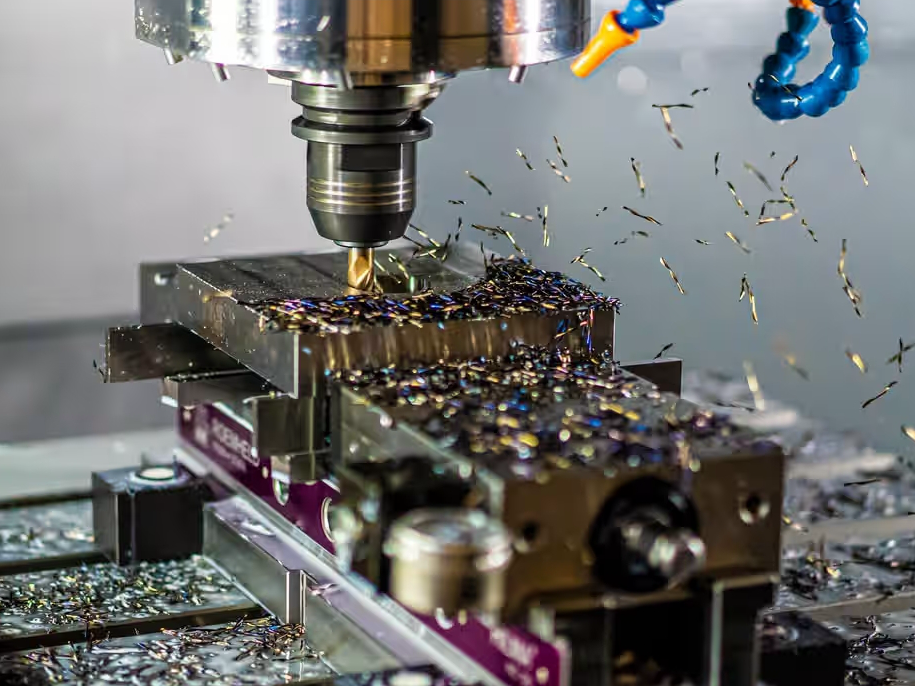

Online Precision Machining Manufacturing Service

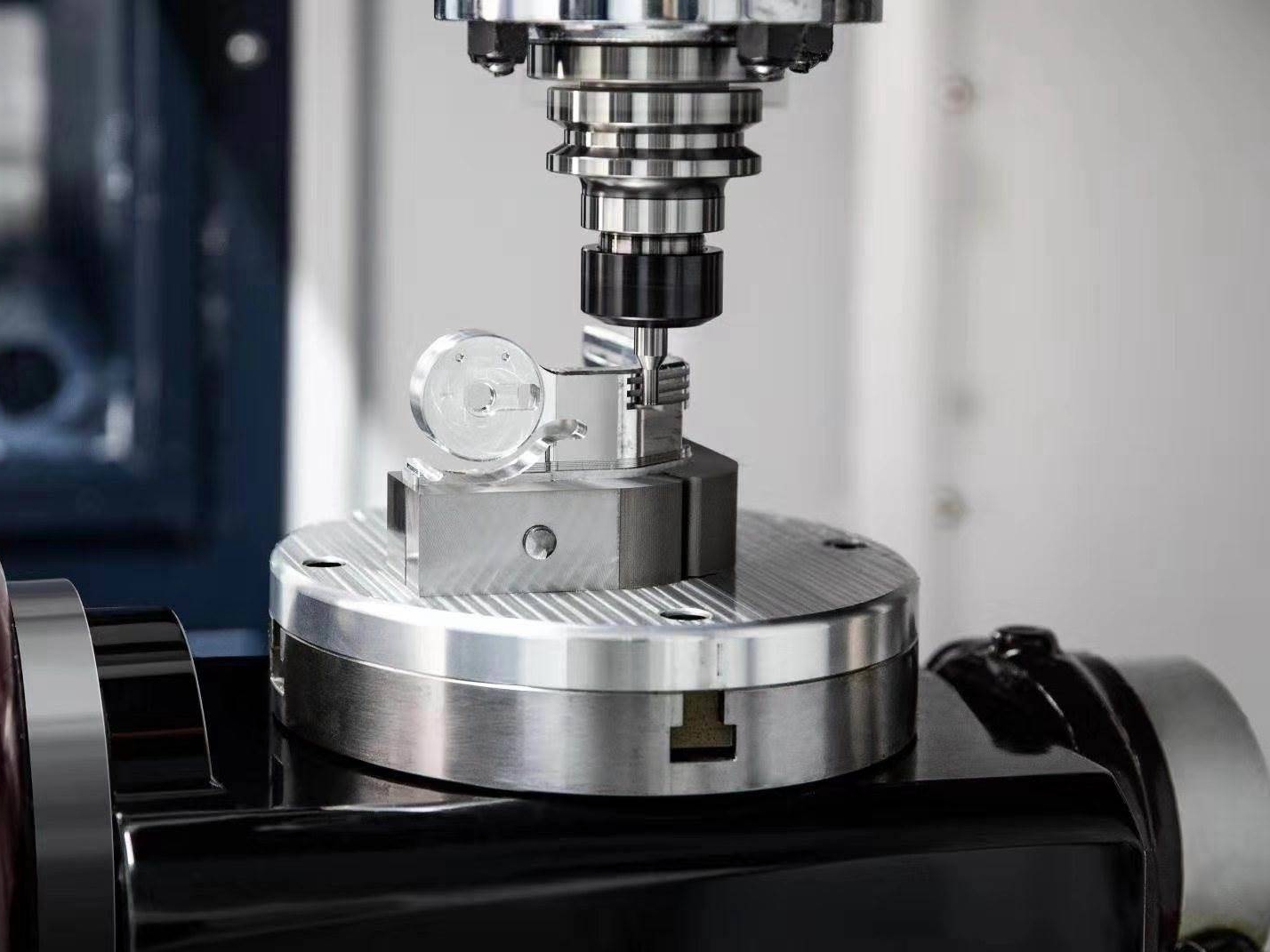

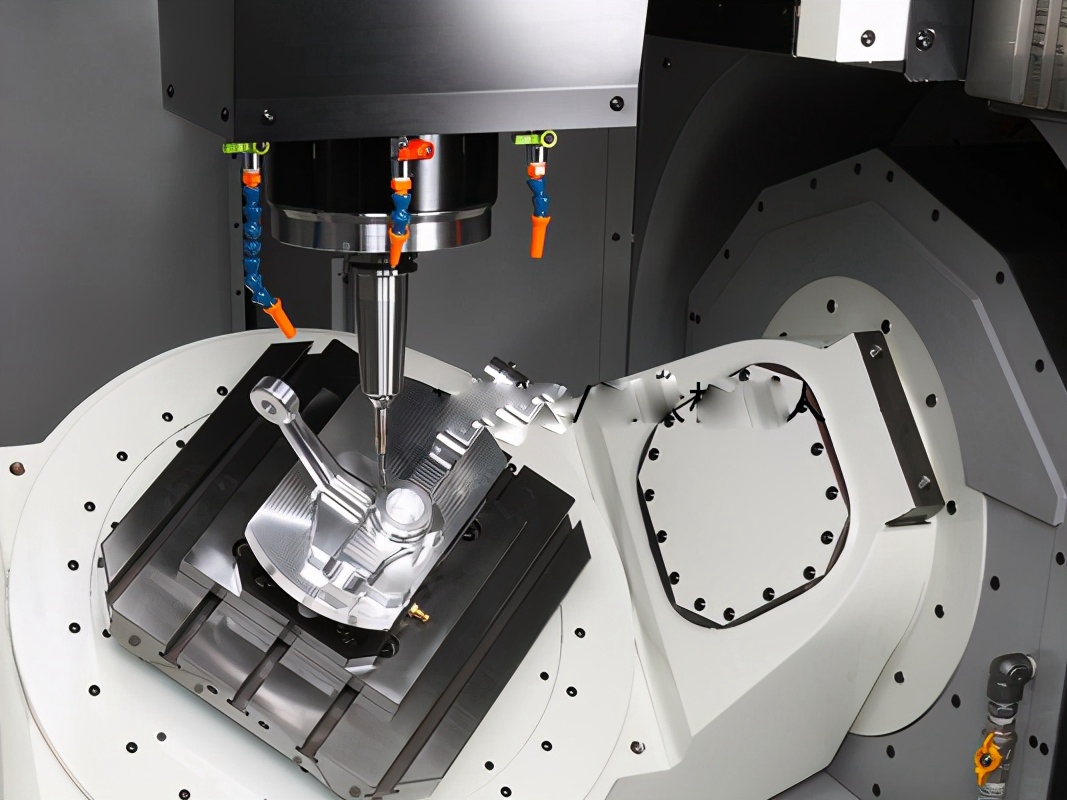

Our On-Demand Precision CNC Milling Service is tailored to meet the most exacting standards for industries requiring high-quality, reliable, and efficient superalloys, ceramic, stainless steel, aluminum, and titanium parts CNC milling solutions.

- Rapid Precision Machining Prototyping Service

- Low Volume Precision Machining Service

- Precision Machining Mass Production Service

- One Stop Precision Machining Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

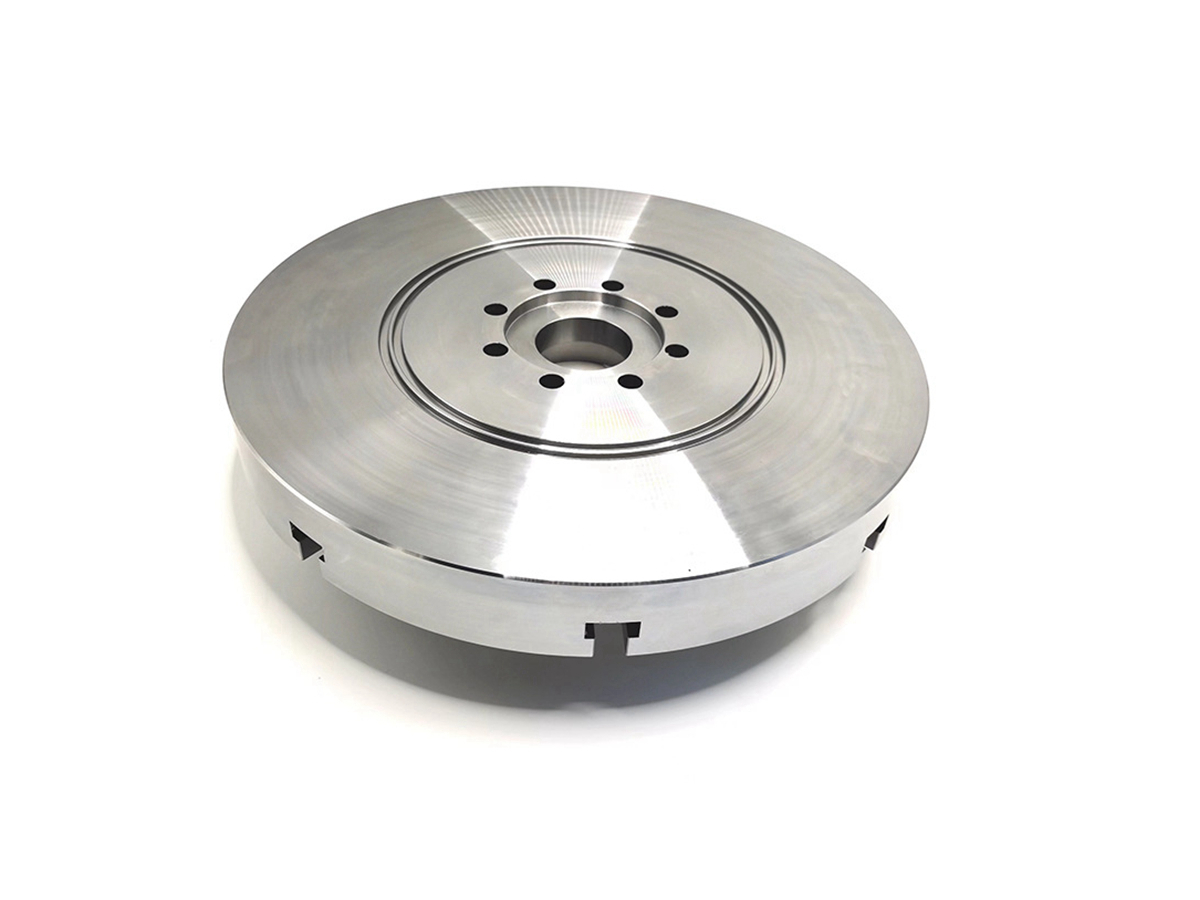

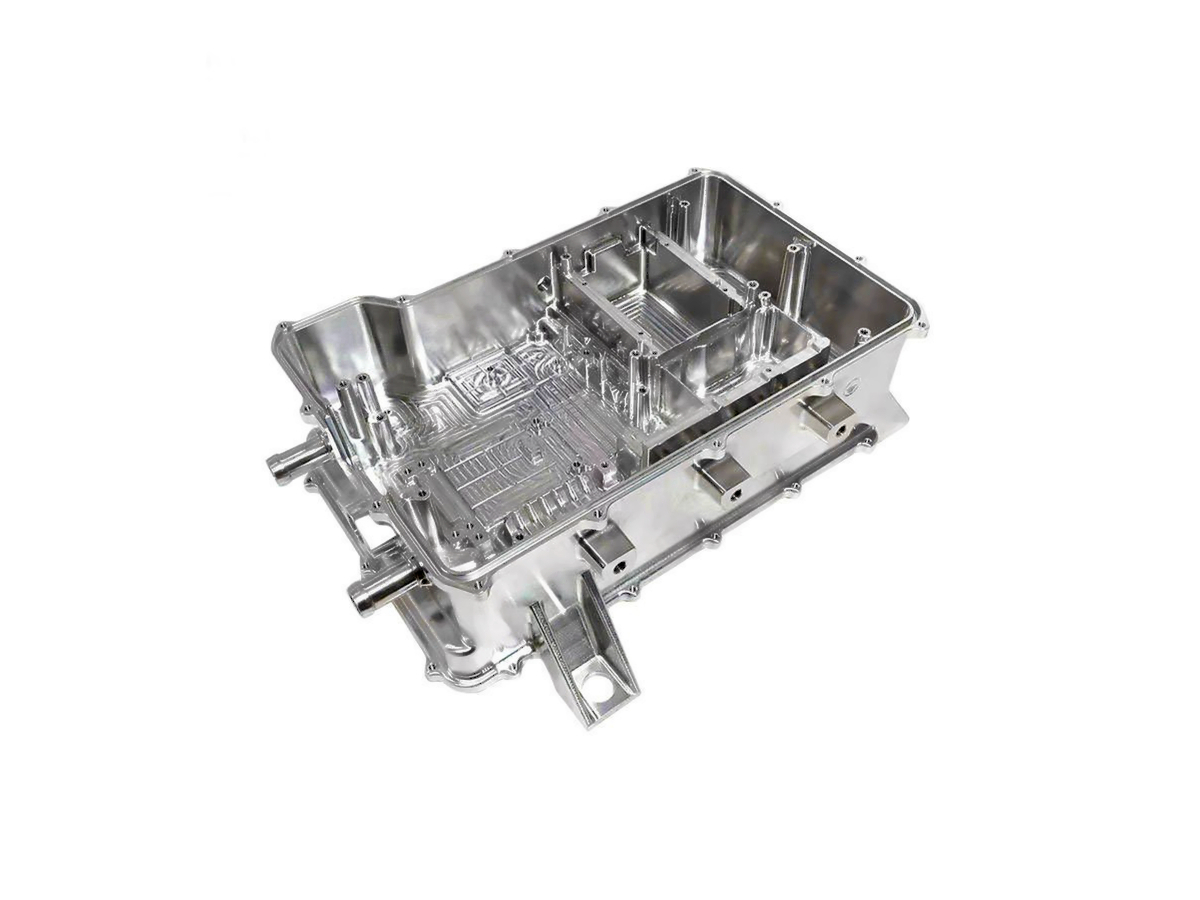

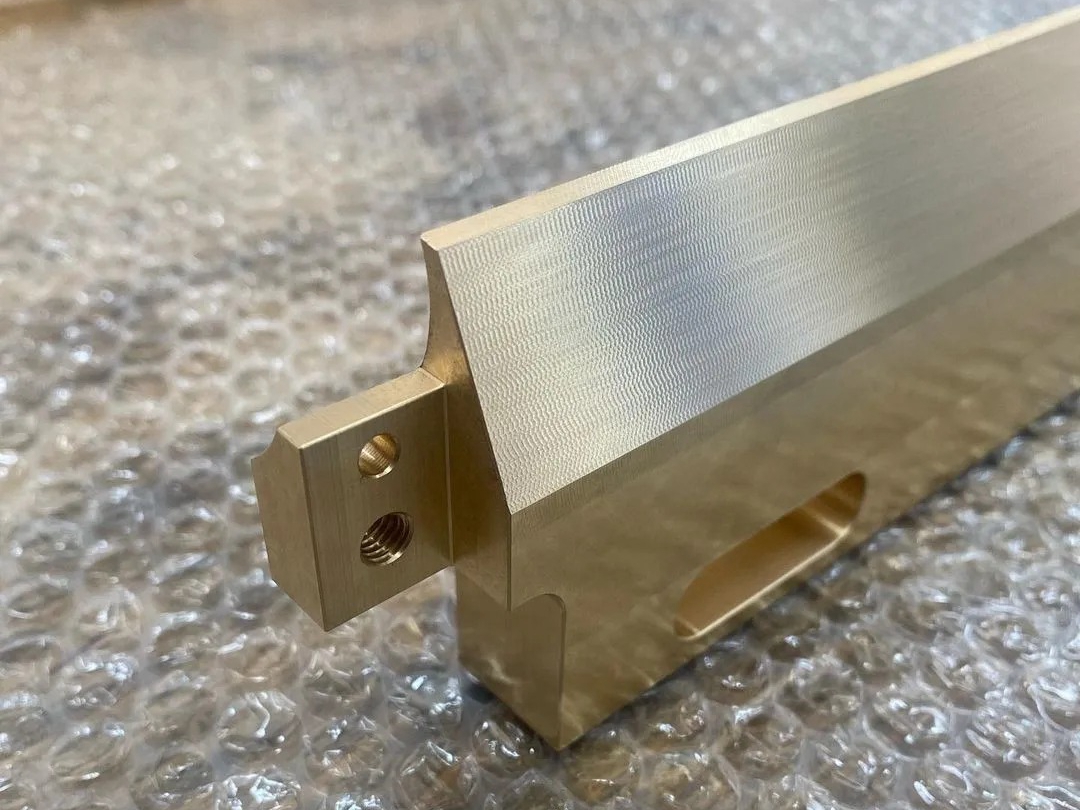

Custom Parts Precision Machining Manufacturing

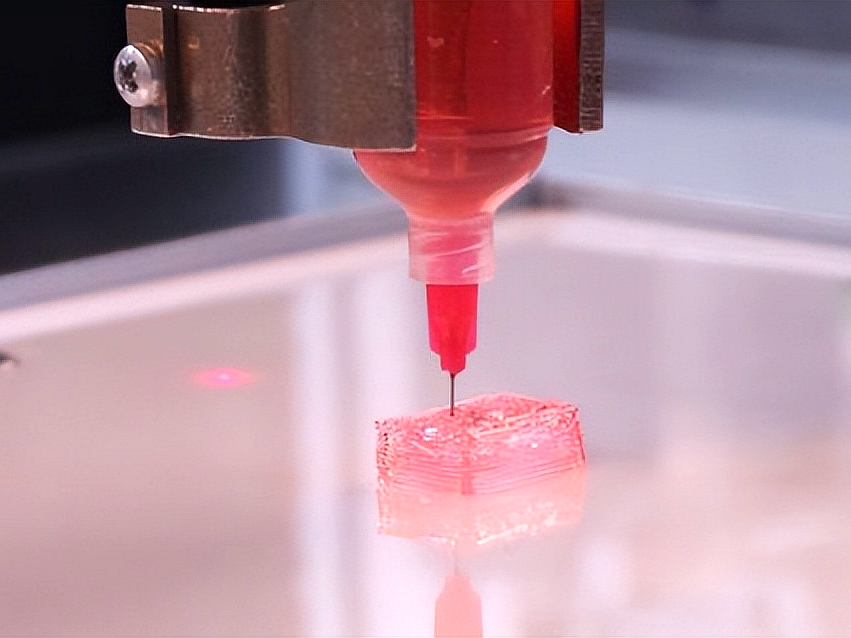

Custom Parts Precision Machining Manufacturing specializes in producing high-tolerance, complex parts tailored to specific requirements. Using advanced CNC technologies, we ensure superior accuracy, surface finishes, and material properties, providing reliable components for industries like aerospace, automotive, and medical devices.

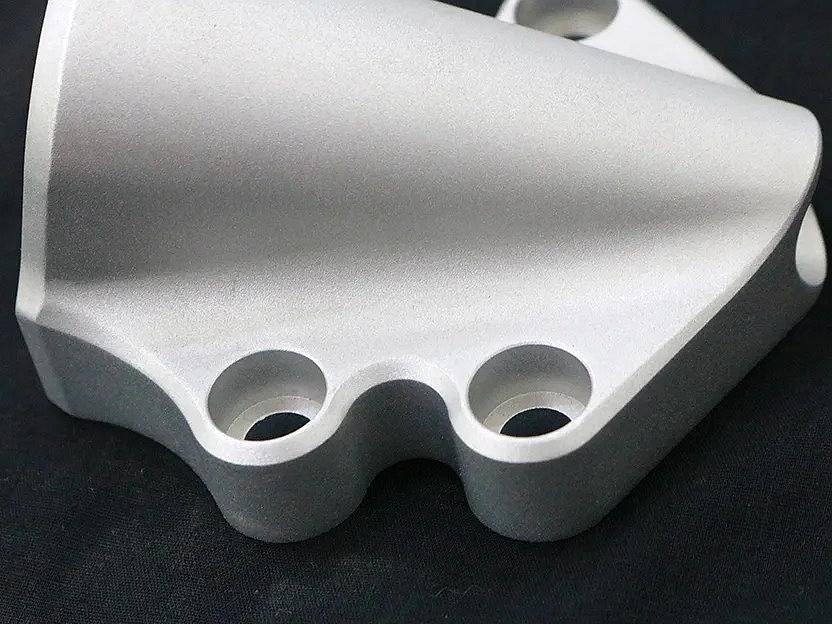

Custom Parts Precision Machining Applications

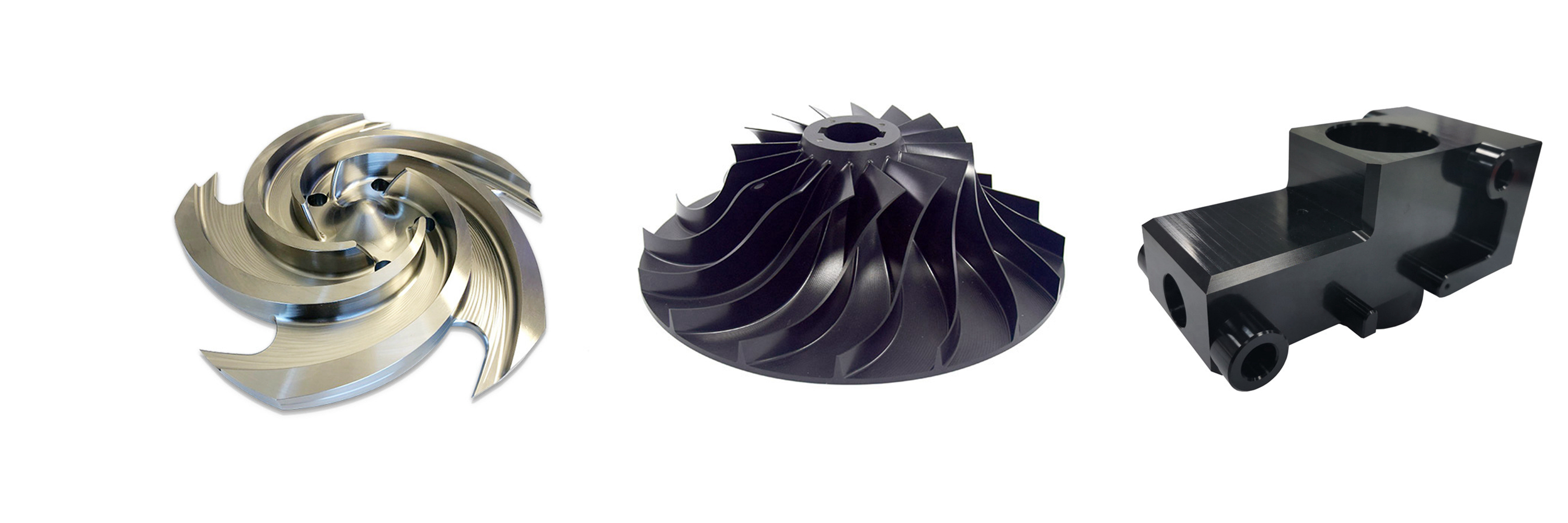

Custom parts precision machining applications involve creating highly accurate, tailored components for various industries, including aerospace, automotive, medical, and industrial sectors. These applications ensure superior quality, tight tolerances, and optimal performance, meeting the specific requirements of each project.

Key Materials for Precision Machining

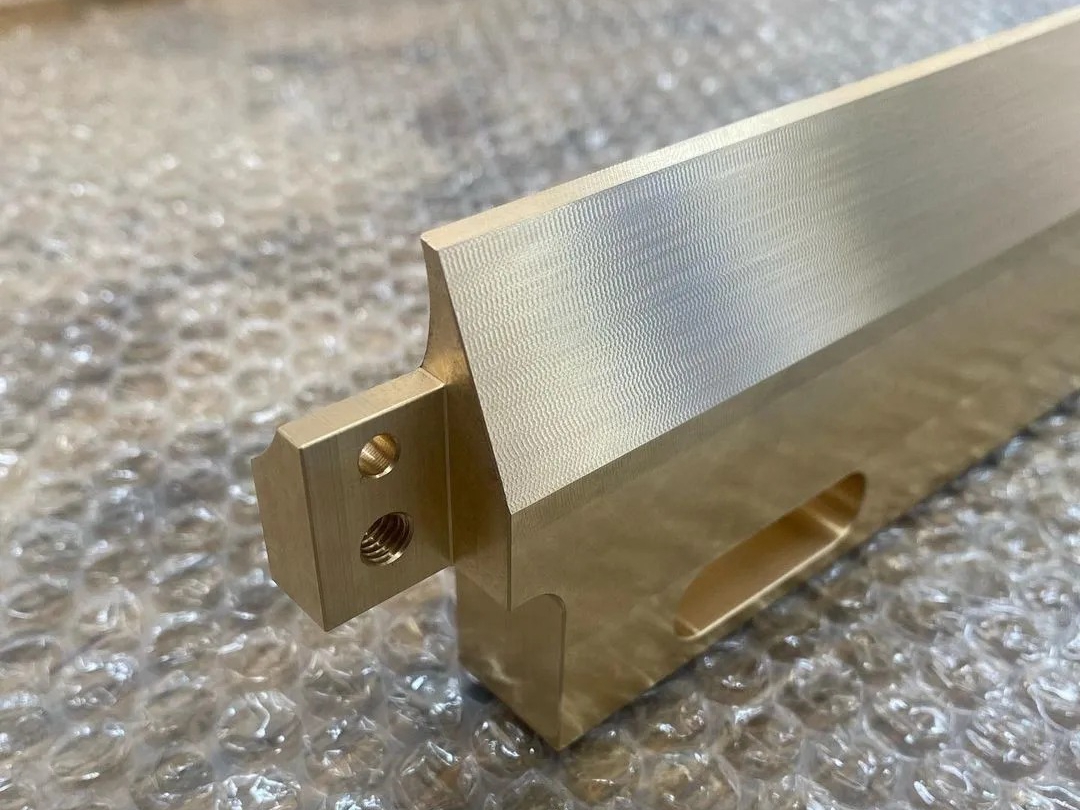

Precision machining materials include a range of metals and composites, each offering unique properties for various applications. Superalloys, titanium, aluminum, copper, brass, and bronze are valued for strength, heat resistance, and durability. Carbon and stainless steels provide toughness, while plastics and ceramics are used for lightweight, corrosion-resistant, and high-precision components. These materials cater to industries like aerospace, automotive, and medical.

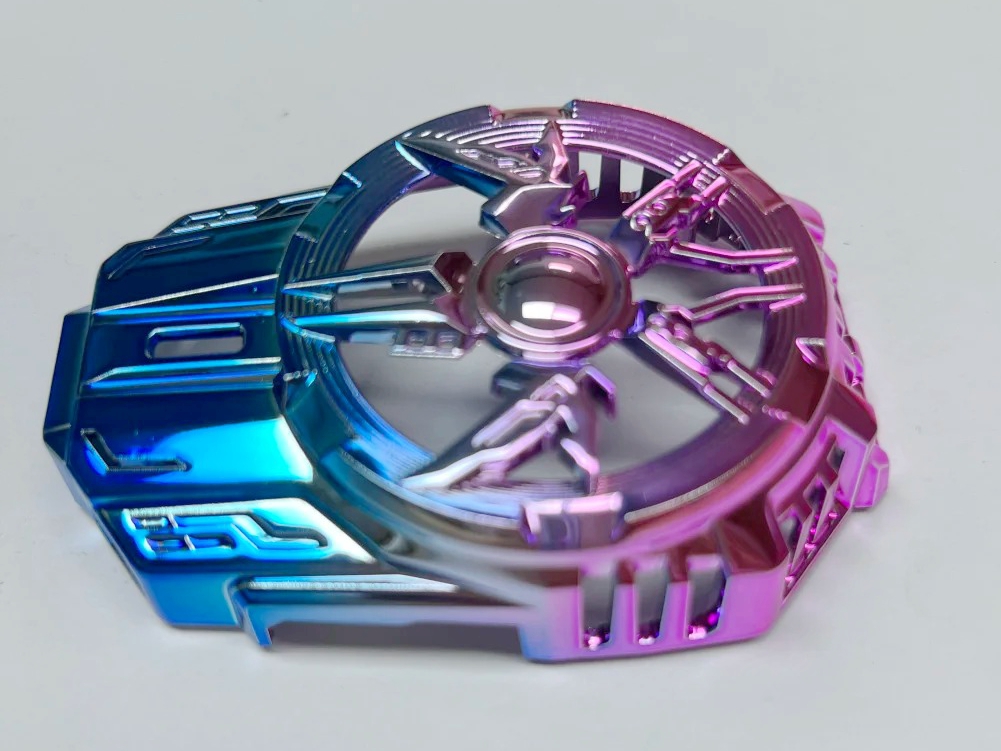

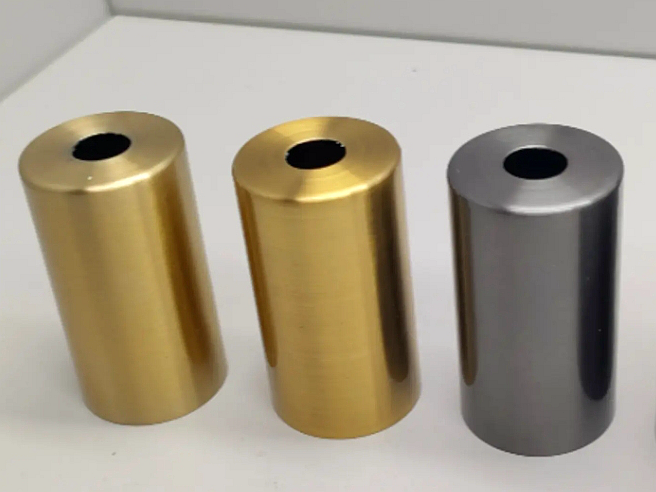

Surface Treatments for Precision Machined Parts

Surface treatments for precision machined parts enhance durability, corrosion resistance, and aesthetics. Techniques like anodizing, plating, polishing, and coating ensure optimal performance and longevity, meeting industry-specific requirements for aerospace, automotive, medical, and other high-demand applications.

learn more

Thermal Coating

learn more

As Machined

learn more

Painting

learn more

PVD (Physical Vapor Deposition)

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

Passivation

learn more

Brushing

learn more

Black Oxide

learn more

Heat Treatment

learn more

Thermal Barrier Coating (TBC)

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

UV Coating

learn more

Lacquer Coating

learn more

Teflon Coating

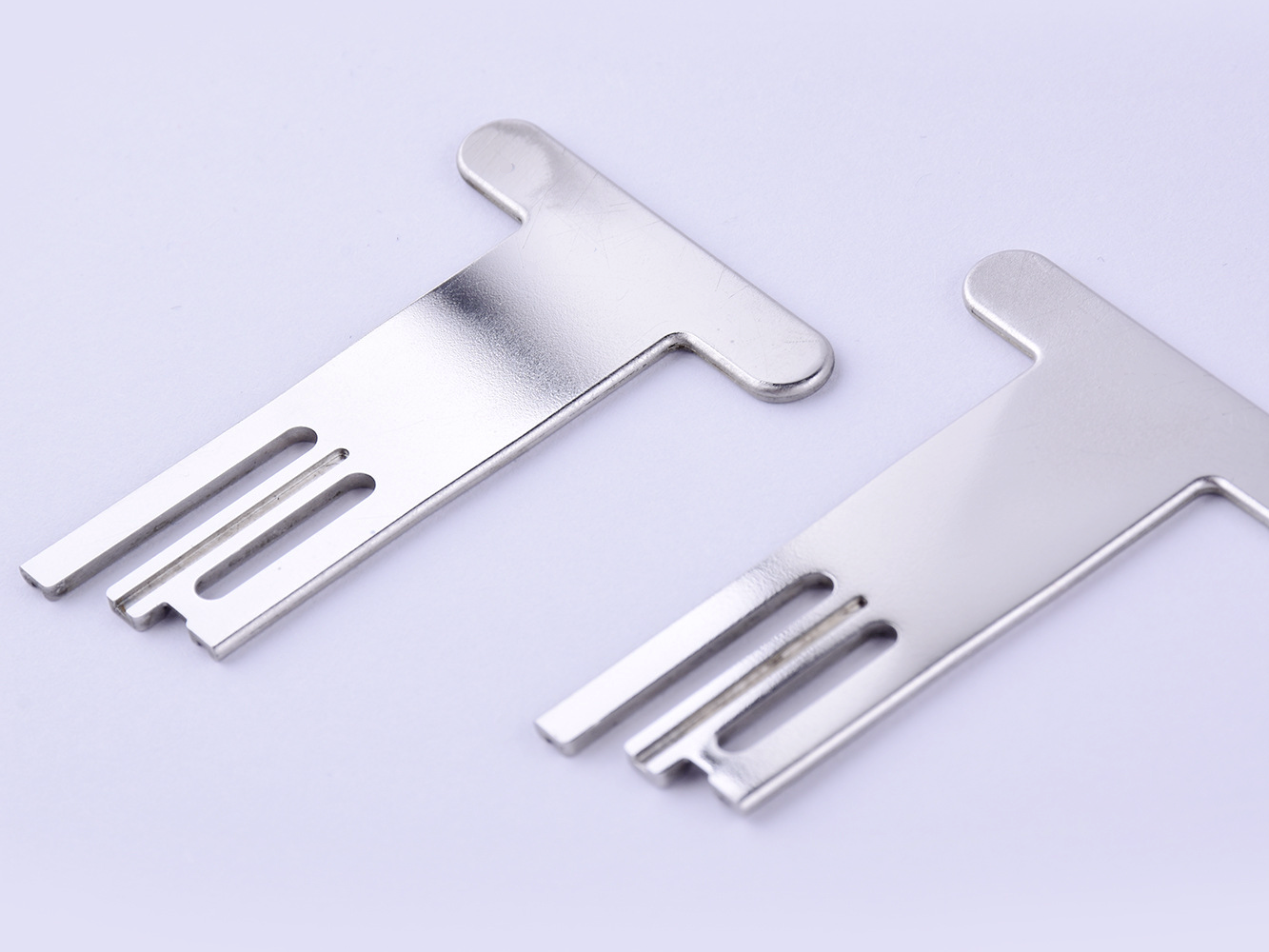

Precision Machined Parts Case Study

A precision machined parts case study showcases real-world applications, demonstrating the ability to produce high-quality components with tight tolerances. It highlights the process, challenges, and results, offering insights into how precision machining solves complex engineering problems across industries.

Let's Start A New Project Today

Precision Machining Tolerance Suggestion

Precision machining tolerance suggestions provide guidance on achievable limits for part dimensions, ensuring accuracy and functionality. By selecting appropriate tolerances based on material, design, and application, manufacturers can optimize performance, reduce costs, and meet quality standards effectively.

Precision Machining Design Suggestions

Precision machining design suggestions provide essential guidelines to optimize part manufacturability. By considering factors like radii, hole design, surface finish, and material selection, these suggestions ensure efficient production, reduce costs, and maintain high-quality standards for complex components.